Commercial mushroom cultivation is an interesting and potentially very profitable business idea, both for people looking to set up their first company and for seasoned investors. However, making a decision about starting a mushroom farm is only the beginning of the whole process. There are many things that a prospective mushroom growing farm owner will need to consider.

How much does it cost to grow mushrooms? What commercial mushroom growing equipment is necessary to start with? Is the investment required for a mushroom farm worth it? We’ll answer those questions (and many more) in our complete guide on how to start mushroom farming, available below. Read on to find out all you need to know to start a successful farm!

Starting a mushroom farm – is commercial mushroom growing a good investment?

Starting a mushroom farm might seem like a niche idea at first, but the truth is that it’s already a big market (although there’s still plenty of space for new investors) that is poised to only grow bigger in the coming years.

According to MarketsAndMarkets’ Mushroom Cultivation Market Global Forecast, the mushroom cultivation market is already estimated to be worth USD 16.7 billion in 2020.

What’s more, it’s projected to reach a value of USD 20.4 billion by 2025, with a Compound Annual Growth Rate (CAGR) of 4%. This is thanks, in part, to the rising popularity of mushrooms as a healthy food source.

How to start a mushroom farm? Step-by-step instructions

While everyone’s experiences with commercial mushroom growing can more or less vary, depending on circumstances, certain things are universal.

Some of the steps that need to be taken while starting a mushroom farm are more generic and are important while setting up a business in any industry, while others are specific to mushroom cultivation.

Either way, they are necessary for the farm to start on the best possible note. Here are the most important ones!

Check the local regulations and complete the formalities

Commercial mushroom growing is gaining popularity all over the globe, from North America, through Europe, all the way to Asia. Each country (or even state, province or other smaller administrative division) can have its own regulations in regards to taxes, labor laws and production of food, among other things.

That’s why it’s important to check the current legislation in your area. In particular, whether the farm needs to meet any specific conditions, acquire permits and licenses and so on.

After gathering the necessary information, you can officially open your business (usually by applying to the right authority). Make sure that you meet all of the requirements – this way, the business will be able to operate legally and safely.

Starting a mushroom farm requires local market analysis

Every business should be aware of who its potential customers are and what they want. Otherwise, it’s going to be hard to meet their expectations.

There are many routes that a commercial mushroom growing farm can take. It’s possible to sell the mushrooms directly to supermarkets and stores, for example, but also to go through intermediaries which will redistribute the products to different clients.

Think not only about what opportunities you can see in your market, but also about the challenges. Check who your competitors are – which mushrooms they offer, at what prices, and what are their biggest advantages and disadvantages.

It’s worth reading customer reviews for other mushroom growing farms to see what kind of things are being praised (for example, good pricing, always meeting the deadlines, efficient customer service) and what are the biggest complaints.

Select a location worth starting a mushroom farm in

One of the most important tasks during the process of starting a mushroom farm is selecting the right location.

The location has an impact both on the costs of building the hall and the employment of staff (in more remote locations qualified staff might be hard to come by, but in areas populated by many businesses workers usually expect higher rates).

There needs to be enough space for the planned initial amount of mushrooms (and preferably some free space to increase the production at some point). Many mushroom growing farms are located on the outskirts of cities, but not all of them.

Acquire the necessary mushroom farming equipment

Good mushroom farming equipment is the backbone of the business. While mushroom cultivation has been going on for hundreds, if not thousands of years, currently it looks much different, especially on the commercial level.

Modern equipment allows for a lot of automation, which means saving time and the workers’ energy. It also ensures the efficiency and precision of the completion of all tasks associated with running a profitable mushroom farm.

Watering the mushrooms, providing the right climate, picking, weighing and so on are faster and easier thanks to presently available machines, tools and devices. The most important pieces of mushroom farm equipment that need to be acquired first include:

● shelving

● growing nets

● mushroom picking lorries

● climate control

● lightning of the mushrooms

● watering system

● mushroom scales

● mushroom picking knives

● crates.

● machines for filling and emptying compost (for compost phase 3)

It’s hard to imagine a successful mushroom growing farm without them. Each plays an important role in the day-to-day work associated with running such a farm.

Shelving

Shelving is where all the magic happens in a mushroom growing farm, i.e., it’s where mushrooms grow during the cultivation period.

It needs to be, above all else, resistant to the conditions in a mushroom farm as well as to mechanical damage.

Shelves made of aluminum are distinguished by their long service life, especially compared to some of the alternatives. They can serve a mushroom growing farm for many decades, unlike galvanized shelving, for example, which usually needs to be replaced much more frequently.

Frequent replacements equal high costs (both due to the cost of new shelving, and disruption of the work connected with having to install it), which is not optimal for any business. Aluminum shelving allows the farm to save money in the long run. It’s safe from corrosion, easy to assemble and ensures better light dispersion in the growing rooms due to its brighter color.

Growing nets

Growing nets are used for placing the compost on the shelves of the shelving and pulling it out after use. Lower quality ones have a tendency to narrow with use, there’s also the possibility of holes starting to appear and of the compost falling off the shelves.

Lower quality ones have a tendency to narrow with use (falling of the compost off the shelves), there’s also the possibility of tearing/ cracking.

It can cause stopping the loading process (expensive downtime) or boiling of the compost (during the summer period).

Meanwhile, high-quality nets can last for many years without any problems. They can be made from many different materials, but there’s one that visibly stands out: polyethylene. Polyethylene growing nets are easy to clean, hygienic and durable (unlikely to shrink, narrow and so on), therefore they are the best solution.

The most important feature is quality of the material used and, what is crucial, polyethylene yarn weave and also its grammage per m2.

Mushroom picking lorries

Mushroom picking lorries are machines used to allow the pickers to reach every shelf of the shelving in a growing room and to move along the shelves and between growing rooms with the appriopriate (constant) speed, regardless of the size of the load on the platforms (especially during horizontal movement).

They are one of the most sophisticated, complex pieces of equipment in mushroom growing farms, so it’s key to choose the right ones (as well as the right supplier, who will provide excellent customer service and help with maintenance, replacement parts and so on).

What features make mushroom picking lorries efficient?

Modern mushroom picking lorries are designed in a way that allows for easy picking from the top and bottom shelves of the shelving, which ensures that no mushrooms will be missed, without the need to invest in any additional equipment.

High-quality models allow automatic movement of the platform (up and down, as well as left and right), due to special electric drives

This solution is much more efficient and less physically demanding on workers (pickers) than the old ones, which required the pickers to manually move the trolleys by pushing the shelving away.

Currently, all they need to do is use simple remote control and the platform will move without the need for any physical exertion.

It’s important to choose models that have optimal battery capacity. There has been a lot of progress made in batteries used in mushroom picking lorries over the years. Right nowsome high-quality lorries have a capacity which ensures up to 40 hours of work on one charge, allowing for continuous work throughout the entire shift without having to pause the picking for a recharge.

That allows to continue the work throughout the entire shift without having to pause the picking for a recharge or, depending on working system, allows to work throughout two or three shifts with horizontal drive working all the time.

Those features (and many more) lead to noticeably higher harvesting efficiency per hour, which in turn positively affects the farm’s overall profitability. However, efficiency is not the only thing that should be taken into account when choosing mushroom picking lorries. Safety is also extremely important.

Most important safety features in modern mushroom picking lorries

One of the main risks connected with mushroom driving lorries is that they could potentially hit someone or something that suddenly appeared in its path. Such a collision could have devastating consequences. Relying only on human reflexes to prevent them wouldn’t be enough. Even a few seconds of distraction can lead to a tragedy.

That’s why modern mushroom picking lorries use state-of-the-art stoppage systems, which are able to detect any obstacles in the lorry’s path and automatically stop it in the blink of an eye. To ensure that all electrical systems and features will always work correctly, the electrical box needs to be safe from flooding, mechanical damage and other dangers.

There also are many important safety features that don’t require electricity and are just examples of smart engineering. For example, the door to the lorry, or to be more precise – the way it closes. It would be dangerous if it remained open during picking, but there’s no need to install a sensor and lock it automatically. Making it open inwards, thanks to a simple hinge, is a much less complex, but equally as effective option.

Some other things worth paying attention to include hand and arm protection, a non-slip working platform, which ensures stability even in harsh conditions and a rigid, durable frame made of high-quality materials. Heavy-duty, durable wheels, resistant to all of the risks present in mushroom growing farms (like corrosion, among other things), are also very important.

What is very important as well – all-encompassing design including refined and proven solutions also for moving parts, which long-term reliable operation has been confirmed in difficult conditions of the mushroom farm and which guarantees low maintenance costs.

Selection of appropriate quality trolleys (where choice shouldn’t be dictated only by low price) is one of the most important part of the investment. Usually several dozen of trolleys are needed so that means dozens of problems per day – less or more. “The devil is in the details”

Climate control

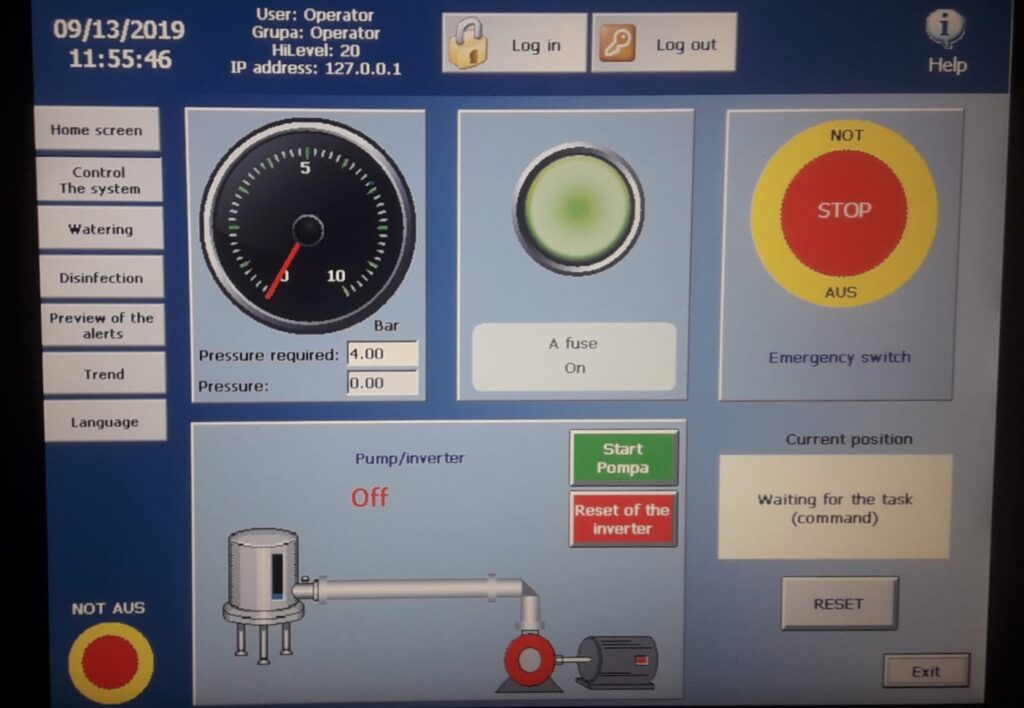

Climate control systems in mushroom growing farms are responsible for maintaining the proper climate (temperature, humidity and so on) in the growing rooms of mushroom growing farms. Such systems are composed of many elements, including, but not limited to, special computers, software, measuring devices, sensors and weather stations.

To make the process of controlling the climate of a mushroom growing farm even easier and more intuitive, modern climate control systems are equipped with large touchscreens. There’s even the possibility of remote control thanks to a mobile app, which means that the farm can be managed at any time, from any place. Responding to changing circumstances and emergencies, as well as analyzing the relevant data and making the right choices, has never been easier.

They are able to control the difference in humidity between the air introduced into the room and the air that’s already in it. Easy to use climate control system full of valuable features can have a real impact on the farm’s overall profitability.

Smart heating and cooling allow for significant savings, not to mention its positive impact on the quality of the mushrooms and the harvesting efficiency, which for obvious reasons also matter as far as profits are concerned.

Lightning of the mushrooms

Lightning of the mushrooms is a necessary piece of equipment for every mushroom growing farm – after all, the employees couldn’t possibly work in the dark. It has to operate in very harsh conditions (temperature and humidity-wise, among other factors), so just any given lamp won’t do. Or rather, lower-quality lamps, not suited to such conditions, will most likely get damaged easily, generating additional costs.

Therefore, it’s crucial to invest in high-quality lamps, made of durable materials. Lamps with housing made of borosilicate glass, which is resistant to high temperatures, are an especially good choice.

Lamps with housing made of borosilicate glass or polycarbonate, which are resistant to high temperatures, with assumption of tightness at the IP68 level in both cases, are an especially good choice.

If a lamp doesn’t meet this condition, it’s unlikely to survive long on the farm, as water can be extremely damaging to electrical components.

What does IP68 mean? IP stands for Ingress Protection, and the first and second digits stand for different things, so they have to be considered individually.

The first one is related to protection against dust. In this case, it’s 6 (the highest possible), which means very high dust protection. The second one is related to water. 8 means that the device can be permanently immersed in water (exact specifications, for example, the matter of acceptable depth of the water, depend on the manufacturer).

Watering system

A technologically advanced, high-quality watering system is a cornerstone of every modern mushroom growing farm. As the name suggests, its main task is to manage the process of watering mushrooms throughout the entire cultivation period.

In good systems, there’s both the possibility of automatic and manual watering. In the first case, the worker selects on which days and times watering should be done, while in the second one the employee starts a one-off watering with a press of a button. ‘Manual’ refers to starting the process manually, but the watering itself is performed without human intervention in both cases.

In both methods (automatic and manual one) there is possibility of adjusting amount of water per m2.

Having the ability to set up a watering schedule according to which the water will be distributed allows the farm to save on labor. It also ensures that there won’t be any unplanned lapses in watering (for example, due to workers’ forgetfulness or short staffing), which could negatively affect the cultivation process.

Modern systems also provide remote access through the Internet, both to the current parameters and graphical diagrams of watering programmes, which helps to control and analyze the situation at the mushroom growing farm even from a large distance.

Mushroom scales

Mushroom scales are used for, as the name suggests, weighting mushrooms after picking them. There are many scales available, but not all will provide the perfect mix of reliability, ease of use and resistance to difficult conditions, which is the right choice for mushroom growing farms.

High-quality sensors, great materials (ABS and stainless steel housings are considered to be very durable) and many modes of operation to choose from are the key factors to consider when making a purchase. It’s also important to check how a given scale is powered – by cable or battery.

Any cable connected to the scale could easily get damaged, whether due to water, humidity, temperature or accidental mechanical (for example, yank off or wrench off). That’s why battery-powered scales are so popular. All they need to function is for the batteries to be replaced from time to time (on average, they should withstand a couple of months of use), which doesn’t require much time and effort.

Avoiding taking care of charging accumulators, saving energy (which is not used for charging) are also advantages and even the best rechargeable batteries have to be replaced, on average, every one or two years.

Mushroom picking knives

Fast, precise mushroom picking requires the use of knives, which are simple and relatively inexpensive (compared to mushroom picking lorries, for example), but important tools without which the mushroom growing farm could hardly function. Picking them at random is a risky choice. The difference in price between the worst and best models is rather small, but the difference in quality is quite big.

Good mushroom picking knives have a durable handle (for example, one made from engineering plastic) and an optimally sharp blade that won’t quickly become dull or damaged. Models with ergonomic, correctly profiled blades made of stainless steel are the way to go. They don’t need to be frequently replaced and allow for efficient, safe work, which means they are very cost-effective.

While ordering mushroom picking knives, it’s worth thinking about engraving them (with company name, number, logo or any other chosen text or symbol) for easier identification.

Crates

Crates allow for easy storing and transport of mushrooms. Like all mushroom growing farm equipment, they need to be able to withstand intensive use and harsh conditions.

When making a selection, it’s important to pay attention to the materials they are made of, their size, as well as factors related to keeping hygienic conditions on the farms (ease of cleaning and so on).

No matter the type of equipment, it’s always crucial to make sure that it will be adapted to the farm’s needs. Most mushroom growing farms use similar types of equipment, but the details can differ depending on the size of the operation, budget and so on. Good suppliers always try to provide their customers with the best products for their circumstances, so it’s best to bet on proven producers with years of experience.

There are two kind of crates -reusable ones and disposable cardboard ones.

Reusable ones, after coming back, are cleaned and used again.

Set up the facility

Mushroom growth for hobby purposes doesn’t require a lot of space and an elaborate set-up, but when it comes to commercial mushroom growing farms, the whole process is much more complex.

Starting a mushroom growing farm

● social, office and sanitary rooms

● communication corridor

● room for machines

● walk-in refrigerator

● loading and unloading ramp

● packing room

● chilled water engine room

● boiler room

There’s also the matter of ensuring access to water, electricity and gas. It’s worth thinking about investing in renewable energy sources right away (especially photovoltaics or geothermal deposits) .

It may be a cheaper and safer solution in the long term than acquiring energy from traditional sources, and the farm can label itself as environment-friendly.

In order to achieve the best possible results, the right climate must be maintained on the farm at all times. Therefore It’s also very important to have high-quality climate control systems (cooling and heating installations), what was mentioned before.

We need to know, if climate control system is efficient enough to ensure different climate conditions in every chamber, in the moment.

Hire the right workers to make starting a mushroom farm easier

Starting a mushroom farm requires some outside help, especially if it’s a large-scale operation. The farm will need people directly involved with mushroom cultivation as well as different types of specialists present in nearly all industries.

The first group includes pickers, foremen, drivers and technologists/quality controllers (they are especially important since they are responsible for setting up the entire cultivation process).

If you are completely green in the area of how to farm mushrooms, getting help from an expert in the field will be priceless. Know-how built over many years of experience in the industry will be helpful in a myriad of ways.

However, it’s worth noting that some tasks, like marketing ones, can be outsourced to outside agencies. It can be a much cheaper and simpler option, especially for small farms that are just starting out.

Ensure effective management

A properly managed mushroom growing farm will operate like a well-oiled machine and generate satisfactory profits. But what does good management require? Among other things, fast and precise counting and recording of the efficiency of the picking and worker’s labour in general.

The presence of technologists, who manage the cultivation process (including supervision of climate control systems, watering system, filling system, etc.), is also extremely important. Equally important is the supervision of the picking, which is the responsibility of technologists and foremen.

Prepare a website and visual identity

If a farm wants to attract potential customers and build brand awareness, it has to be visible on the Web. A high-quality website and well-managed social media profiles are also important.

Some other important factors include an appropriate name and consistent visual identity. Like any other company, a mushroom growing farm should have a catchy and easy to remember (and spell) name. This way, if someone hears it once or twice, they should be able to recall it when needed.

Visual identity consists of the company’s logo, as well as color palette, fonts and other visual elements associated with the brand. Keeping these things consistent all across the board (on banners, the website, packaging) improves brand awareness.

What is the cost of starting a mushroom farm?

There’s no simple answer to the question of how much does it cost to grow mushrooms. The cost of starting a mushroom farm can vary depending on many factors, such as the size and type of mushroom farm you want to create.

Main investments expenses are to buy a building plot, to place buildings, to buy mushroom cultivation equipment, to hire employees, marketing etc.

Of course it is possible to start with small size farm, but as we observe in the era of market consolidation, beginning business on to small a scale, can lead to too low competitiveness, what in turn can lead to unsuccess.

It is worth to take under consideration growing bio mushrooms, what has become a trend recently. We believe this trend will continue to develop in the future.

It is worth also to consider possibility of obtain government subsidies to start a business, what could make the beginning of the investment easier.

At the first glance, the steps outlined in this article might seem overwhelming. In reality, a lot of people have already managed to set up profitable mushroom growing farms and it’s likely that many more will also be able to do so. Therefore, there’s no need to be discouraged.

To ensure the highest possible probability of success, it’s important to seek expert advice and avoid unnecessarily cutting corners. For example, high-quality commercial mushroom growing equipment might be more expensive than lower-quality models, but it won’t require frequent servicing and replacement, thus allowing the farm to save money in the long term.

Modern, technologically advanced equipment, such as mushroom picking trolleys, aluminum shelving, growing nets and much can be acquired from proven suppliers, such as GROWTIME. GROWTIME is an experienced manufacturer of mushroom farm equipment used by leading farms around the world, focused on providing efficient, safe and durable solutions.