Components of the system and technical data

- Pressure pump: 5,5 kW; 3 phase 230 / 400 V,

- Plastic tank 3500 liters with certificate for contact with food,

- The main water installation (from pump by the corridor to the rooms) made from polypropylene pipe PP-75 mm with certificate for contact with food,

- Pipes under the shelves are made from aluminium 28 mm x 2 mm or stainless steel 28 mm x 2 mm

- Connectors between PP pipes and aluminium or stainless steel are galvanized or made from stainless steel,

- Water jets mounted under the shelves every 1,5 m,

- Stop valves (manually operated) mounted every shelf galvanized or made from stainless steel,

- Drain valves (manually operated) mounted every end of shelf – periodic washing, are galvanized or made from stainless steel,

- Electro valves 6/4’ to control irrigation in the room,

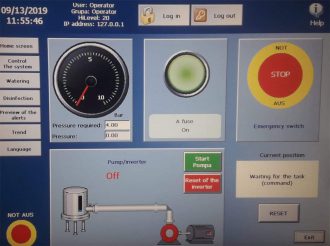

- Inverter controlling the pump to maintain the correct pressure in the system (made by Pedrollo),

- Chemical connection made of PP63 pipes,

- Chemical dispenser with concentration control from 0.2% to 2% (Dosatron DS20),

- Pressure sensor to control pressure in the installation,

- Water flow meter

The main functionality of the system

- Automatic watering at any time of day or night,

- Manual control watering,

- Acces to computer and parameters all the time by internet,

- Graphical diagrams of watering programmes,

The task of the Mushroom Irrigation System gives the management and control of the watering process during the whole cultivation time . The system has the task of watering in manual or automatic mode according to the programmed schedule of individual mushroom rooms.

Mushroom Irrigation System consists of a water system into which water is transported by means of a pump unit controlled by an inverter. The operation of the inverter is managed by a central control unit via EtherCat. The system has pressure and flow sensors that collect information from the main installation and in case lower water pressure than required is recorded – the system will switch on the pump to adjust the pressure. The system controls the pressure every time when watering system is working.

Responsible person of mushroom growing has the possibility to select manual or automatic mode settings. The watering process is the same in both cases, only the way and time of starting the process are changes. The operator of the irrigation system uses the touch panel to select the cultivation room and the amount of water that the system will supply per square meter of cultivation. In addition, it is necessary to make settings on what day of the week and what time the watering should start, so that the system, according to the stored parameters, performs the tasks automatically. The difference between manual mode is that switching on the cultivation room is a manual ‘start watering’ button.

See also: Climate systems for mushroom growing